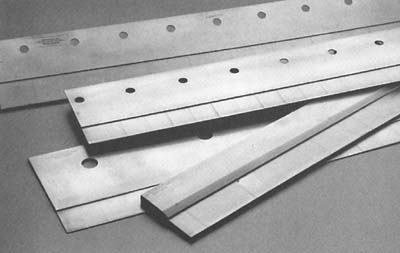

Segmented Ink Blade

(Doctor/Ductor Blade)

The Ultimate Ink ControlASI's segmented ink blade design gives the pressman total flexibility across the entire ink fountain. Our unique design eliminates inherent problems with solid, sculptured and laser cut blades. The ASI segmented ink fountain blade is not made from one piece of steel that is cut, lasered or milled. ASI's blade gets its start from precision ground (+/- .00005) individual ink keys, whicih are then bonded to a common glue plate. The result are incredible ink control with no side effects.

|

Other Blade Design LimitationsSolid & Sculptured blades physically limit ink control due to blade flex and connecting keys. The result is chasing color, longer make-readies, & reduced color quality. When adjusting one ink key the blade flexes. This flexing changes the ink profile in other areas across the ink fountain. To complicate things further as the pressman adjusts one key that adjustment can impact up to 5 neighboring keys because the keys are connected to each other. Some ink control systems try to help by electronically limiting ink key control through software. The software limits ink key actuator travel based upon the position of adjacent keys. It requires 4.7 x the force to move a solid/sculptured blade compared to a segmented blade, resulting in premature failure of expensive ink actuators. Laser cut blades allow ink to leak through the gap cut by the laser. Laser cut blades require maintenance of foil overlays, foil between segments, and silicon caulking to keep blades from leaking. |